Grammy Nominated Comedian, Actor, Writer, Producer, two-time

New York Times best-selling author, three-time Emmy winning top

touring performer, and multi-platinum-selling recording

artist

Jim Gaffigan is an eight-time Grammy nominated comedian, actor,

writer, producer, two-time New York Times best-selling author,

three-time Emmy winning top touring performer, and

multi-platinum-selling recording artist. He is known around the

world for his unique brand of humor, which largely revolves around

his observations on life. His 11th special, The Skinny, premiered

on Hulu last winter as the streamer's first ever original stand up

special for their new comedy vertical, Hularious, and garnered

almost 100 million clip views online. Gaffigan is currently on

his, Everything is Wonderful standup comedy tour.

Gaffigan is a top ten comedian according to Forbes' most recent

comedy list and top ten earning comedian in Pollstar. He released

his 10th comedy special, Dark Pale, in 2023 on Amazon Prime Video,

an unprecedented achievement for the comedian/actor. Dark Pale was

met with critical fanfare with The New York Times calling it, 'his

best yet.” Gaffigan recently finished co-headlining with Jerry

Seinfeld for a sold-out multi-city arena tour and in May of 2024,

sold out two shows at The Hollywood Bowl during the Netflix Is

Joke Festival.

In 2021 Gaffigan released his 9th special, Comedy Monster, on

Netflix which was nominated for a Grammy Award. He was also

recently awarded for being the first comedian to reach one billion

streams on Pandora.

Gaffigan can currently be seen opposite co-stars Jerry Seinfeld,

Melissa McCarthy, James Marsden, and Hugh Grant in Netflix's

Unfrosted, which debuted as the #1 movie in the world on Netflix

last May. He can also currently be seen as the lead in the

well-reviewed and certified fresh Sci-Fi drama, Linoleum, which

was named one of Vulture.com's best movies of 2023 and is

currently streaming on Hulu after a theatrical release.

Gaffigan starred as Mr. Smee in Disney's Peter Pan and Wendy,

opposite Jude Law and Yara Shahidi. Also premiering recently,

Gaffigan joined the cast of HBO Max's Full Circle, a limited

series from Steven Soderbergh and Ed Solomon which follows an

investigation into a botched kidnapping, connecting multiple

characters and cultures in present day NY.

On the silver screen, his many credits include Three Kings, Super

Troopers 1 & 2, and Chappaquiddick. 2019 was Gaffigan's biggest

year in film to date with an astonishing eight films releasing,

three which premiered at the Sundance Film Festival including

Troop Zero with Viola Davis and Alison Janney, Them That Follow

and Light From Light - with many festival goers and press calling

Gaffigan the “King of Sundance.” Gaffigan was also recently heard

in Disney/Pixar's highly anticipated animated film, Luca, opposite

Jacob Tremblay and Maya Rudolph.

Gaffigan had two films recently in which he debuted as the lead.

The comedic film Being Frank, and American Dreamer, a dark

thriller which features him as a ride share app worker who

moonlights as a private driver for a drug dealer. Gaffigan can

also currently be seen opposite Ethan Hawke in IFC Films Tesla, as

well as opposite Josh Hartnett in Saban Films' Most Wanted.

In addition to two seasons of the critically acclaimed

semi-autobiographical The Jim Gaffigan Show, which he wrote and

produced with his wife Jeannie, Gaffigan has guest starred on many

television comedies and dramas, ranging from Portlandia and Bob's

Burgers to the HBO cult hits Flight of the Concords to dramatic

roles in Law & Order.

Gaffigan regularly does humorous commentaries on CBS Sunday

Morning for which he has won 3 Emmys. In 2018 Jim served as master

of ceremony at The Al Smith Memorial dinner. In 2015, Gaffigan had

the great honor of performing for Pope Francis and over 1 million

festival attendees at the Festival of Families in Philadelphia.

He and his wife currently live in Manhattan with their five loud

and expensive children.

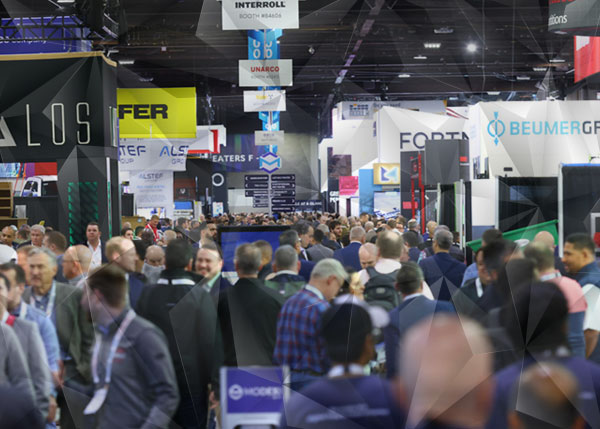

SUPPLY CHAINS.

SUPPLY CHAINS.

MODEX MONDAY

MODEX MONDAY

MODEX TUESDAY

MODEX TUESDAY

MODEX WEDNESDAY

MODEX WEDNESDAY

MHI INDUSTRY NIGHT

MHI INDUSTRY NIGHT

EDUCATION

EDUCATION

SEARCH

SEARCH